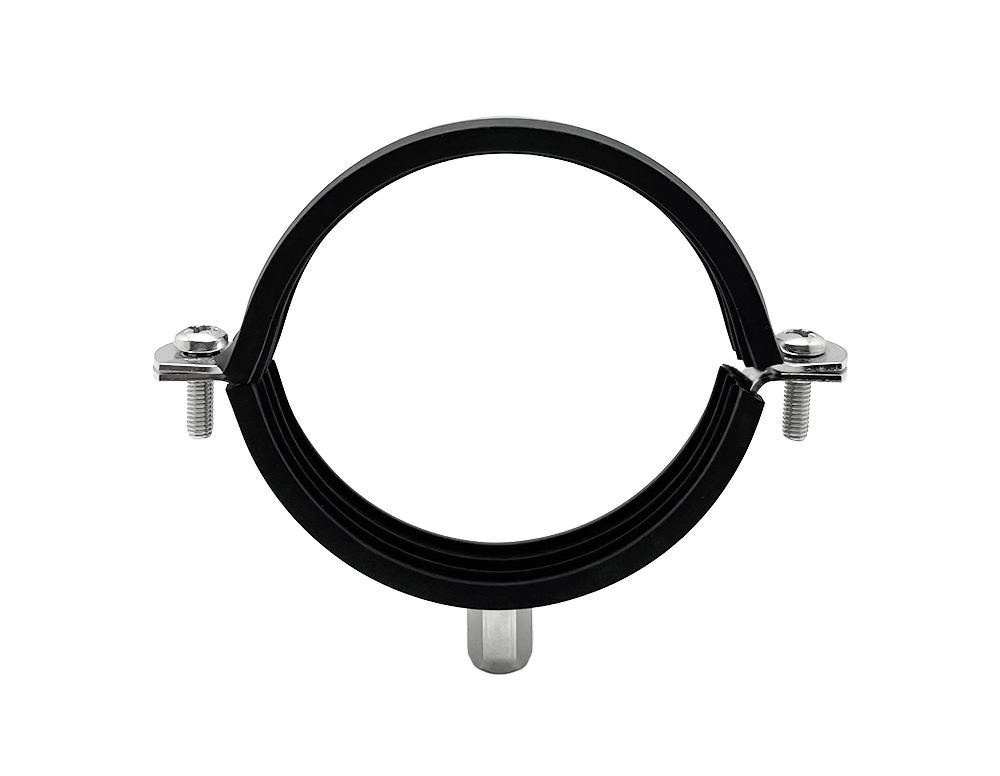

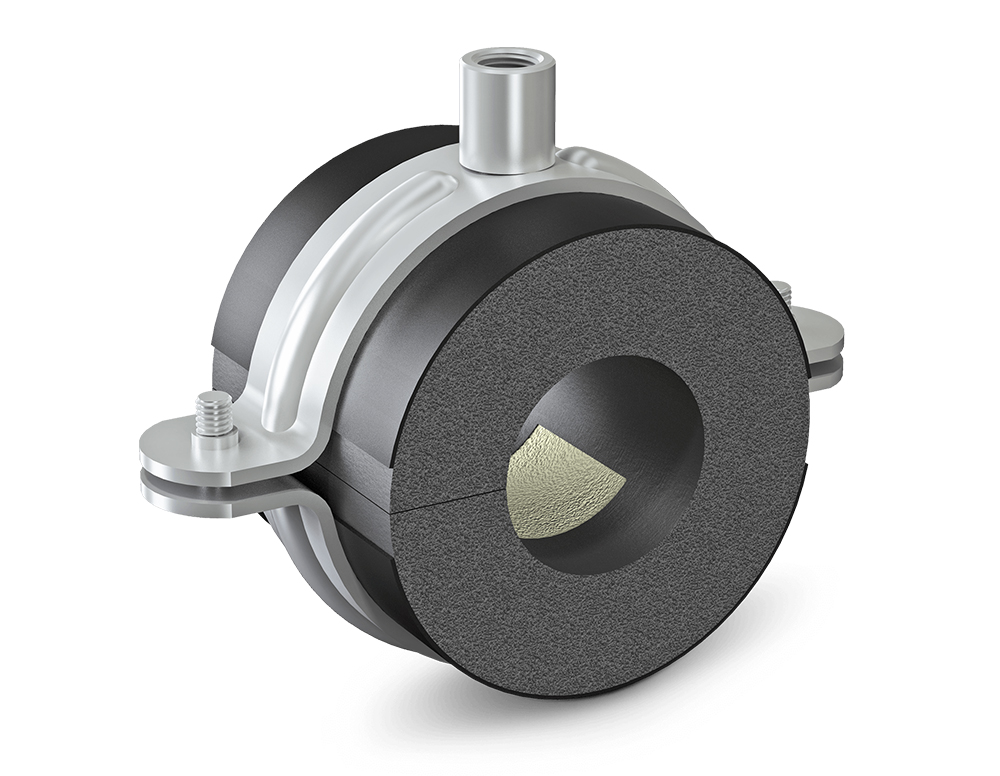

Rubber Lined Pipe Clamps

Technical Specifications:

| Specification | Value |

| Material | Mild Steel. Other Materials Like Stainless Steel can be provided on request |

|---|---|

| Sizes | 1/8" to 10" |

| Finishes Available | Plain, Electro-Galvanised, Hot-dip Galvanised, Zinc Flake, Epoxy Coated |

| Finishes available | Plain, Electro-Galvanised, Hot-dip Galvanised, Zinc Flake, Epoxy Coated |

| Max Temp | 110° C |

| Types | Dual M8/M10 Nut |

| Rubber Quality | EPDM |

| Max Load | As Per Size |

Application/Details:

Rubber Lined EPDM Pipe Clamp is recommended for mounting pipes against the walls, ceilings and floors. Although, the Rubber Lined EPDM Pipe Clamp is specifically designed for supporting non-insulated stationary pipelines positioned horizontally, it is also used Vertically. Rubber Lined EPDM Pipe Clamp is used for mounting non-insulated (bare) pipes. Installation can be done before or after the pipes are placed in position. Rubber Lined EPDM Pipe Clamp provides exceptional stability and support, making it an ideal choice for securing pipes along the roof or other horizontal surfaces. The EPDM lining offers superior support and resistance. Whether for industrial or commercial applications, our Rubber Lined EPDM Pipe Clamp not only enhances the structural integrity of your piping system but also helps prevent vibrations and noise, contributing to a more efficient and quieter operation. Trust in our Rubber Lined EPDM Pipe Clamp to deliver reliable performance and support.

Industries:

Rubber Lined EPDM Pipe Clamp widely used in HVAC industry, MEP (Mechanical, Plumping, Electrical) industries, Firefighting industry, BUILDING AND INFRASTRUCTURE industry, HARDWARE, DEFENCE, RAILWAYS and AEROSPACE industries.

Construction:

Rubber Lined EPDM Pipe Clamp consists of piece of mild steel shaped to wrap around the pipe. The clamp has EPDM Rubber attached to either side of it body. The pipe is secured using the screws on the sides. This model has Dual M8/M10 nut for mounting.

Technical Sheet:

| Product Code | Nominal Pipe Size | Pipe OD | Range | Nut Size | Side Screw | Max Load | Width | |

| (IN) | (MM) | (MM) | (MM) | (A) | Size | (KG) | (MM) | |

| DURAFIX-A-01001 | 1/8" | - | - | 11-14 | M8 X M10 | M6 | 450 | 19-20 |

|---|---|---|---|---|---|---|---|---|

| DURAFIX-A-01002 | 1/4" | - | - | 14-19 | M8 X M10 | M6 | 450 | 19-20 |

| DURAFIX-A-01003 | 3/8" | DN10 | 17.1 | 18-21 | M8 X M10 | M6 | 450 | 19-20 |

| DURAFIX-A-01004 | 1/2" | DN15 | 21.3 | 20-25 | M8 X M10 | M6 | 450 | 19-20 |

| DURAFIX-A-01005 | 3/4" | DN20 | 26.7 | 26-30 | M8 X M10 | M6 | 450 | 19-20 |

| DURAFIX-A-01006 | 1" | DN25 | 33.4 | 32-36 | M8 X M10 | M6 | 450 | 19-20 |

| DURAFIX-A-01007 | 1 1/4" | DN32 | 42.1 | 38-43 | M8 X M10 | M6 | 450 | 19-20 |

| DURAFIX-A-01008 | 1 1/2" | DN40 | 48.2 | 47-51 | M8 X M10 | M6 | 450 | 19-20 |

| DURAFIX-A-01009 | - | - | 54 | 53-58 | M8 X M10 | M6 | 450 | 19-20 |

| DURAFIX-A-01010 | 2" | DN50 | 60.3 | 60-64 | M8 X M10 | M6 | 450 | 19-20 |

| DURAFIX-A-01011 | - | - | 70 | 68-73 | M8 X M10 | M6 | 450 | 19-20 |

| DURAFIX-A-01012 | 2 1/2" | DN65 | 73 | 74-80 | M8 X M10 | M6 | 600 | 19-20 |

| DURAFIX-A-01013 | - | - | 83 | 81-86 | M8 X M10 | M6 | 600 | 19-20 |

| DURAFIX-A-01014 | 3" | DN80 | 88.9 | 87-92 | M8 X M10 | M6 | 600 | 19-20 |

| DURAFIX-A-01015 | - | - | - | 93-99 | M8 X M10 | M6 | 600 | 19-20 |

| DURAFIX-A-01016 | 3 1/2" | DN90 | 101.6 | 99-105 | M8 X M10 | M6 | 600 | 19-20 |

| DURAFIX-A-01017 | - | - | 110 | 107-112 | M8 X M10 | M6 | 600 | 19-20 |

| DURAFIX-A-01018 | 4" | DN100 | 114.3 | 113-118 | M8 X M10 | M6 | 600 | 19-20 |

| DURAFIX-A-01019 | - | - | 125 | 125-130 | M8 X M10 | M6 | 600 | 19-20 |

| DURAFIX-A-01020 | 5" | DN125 | 141.3 | 133-141 | M8 X M10 | M6 | 600 | 19-20 |

| DURAFIX-A-01021 | - | - | 150 | 142-150 | M8 X M10 | M6 | 600 | 19-20 |

| DURAFIX-A-01022 | - | - | 160 | 151-160 | M8 X M10 | M6 | 600 | 19-20 |

| DURAFIX-A-01023 | 6" | DN150 | 168.3 | 159-166 | M8 X M10 | M6 | 600 | 19-20 |

| DURAFIX-A-01024 | - | - | 200 | 200-210 | M8 X M10 | M6 | 600 | 19-20 |

| DURAFIX-A-01025 | 8" | DN200 | 219.1 | 212-219 | M8 X M10 | M6 | 950 | 19-20 |

| DURAFIX-A-01026 | 10" | DN250 | 273 | 269-274 | M8 X M10 | M6 | 950 | 19-20 |