Government Recognized Export House

Government Recognized Export House

Various factors which affect the formability of the metal are:

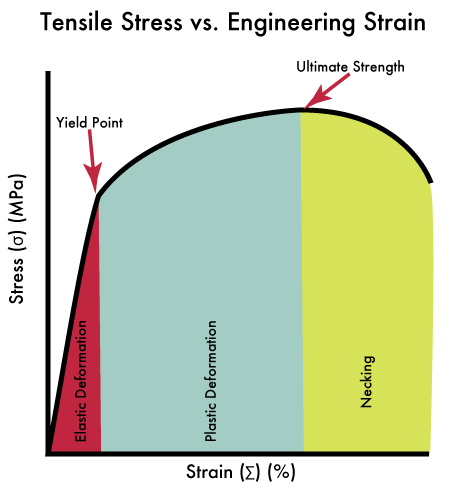

Tensile strength is the ability of a material to withstand a pulling (tensile) force and refers to the breaking strength of a material when applying a force capable of breaking many strands of the material simultaneously, at a constant rate of extension/load. It is customarily measured in units of force per cross-sectional area.

Tensile strength is the amount of load or stress that can be handled by a material before it stretches and breaks. As its name implies, tensile strength is the material’s resistance to tension that is caused by mechanical loads applied to the material. The ability to resist breaking under tensile stress is one of the most important and widely measured properties of materials used for structural applications.

Tensile strength is measured in N/mm2 or MPa and is more important criteria for ductile materials.

The Harder the material the difficult it is to draw and bend. Hence hardness is an important property to be measured while chosing the material.

Hardness can be measured in Brinell, Rockwell or Vickers scale.

However for our application as we handle mostly soft metal Rockwell B hardness is important number for us.

It is the hardness value obtained by applying 980N pressure to the steel ball with a diameter of 1.59mm. It is suitable for measuring soft metals such as nonferrous metals, annealed and normalized steel.

The force applied to bend a standard cross section of metal such that it cannot retrun to it original stage give us the bending strength og a particular metal.

The force applied to Shear a standard cross section of metal such that it gets separated in two parts gives us shearing strength of a particular metal.

It is measured in MPa or N/mm2.

The ease with which the metal can be cut from the parent metal with help of cutting tool refers to as machinability. The chip quality (continuous or brittle chips) would tell a lot about the machinability of the metal.

This will influence the selection of tool material, tooling cost and machine selection for machining of the parts.

Welding is an important process today when completing a part. Most common metals for welding are ferrous metals in particular Mild steel. Common welding methods used are Spot welding, Mig welding, Tig welding, Laser welding etc.

The utility and cost will define which welding method is to be used on that particular material.

This is Steel which is not further worked after hot rolling. The steel slab or plate passes through various rolls to reduce it thickness while it is still red hot.

This enable faster reduction in thickness but gives a coarse grain structure.

Further process like annealing and pickling and oil dipping may be done to make is more formable.

Probably the most common sheet metal used on this plant at the moment is CRCA or Cold Rolled Close Annealed Steel.

The advantages of CRCA steel is that it has better accuracy than HR steel, Better grain structure, readily formable steel, easily weldable steel.

The draw backs are that it is very easily suspectable to moisture content in air and hence can corrode faster.

AT P.P. Impex India we use IS513 CR1, CR2, CR3

Stainless steel is one of the most green metal on the plant as it can be recycled multiple times without losing the desired properties in the end metal.

Steel with more than 10.5% of Chromium gives Stainless properties to it.

Due to its ability to fit corrosion much better and longer then steel, it is on of the preferred material for Medical, Kitchen, Resturants, Marine and automotive applications.

AT P.P. Impex India we use 201J1, 201Cu, 304, 430 grades

Aluminium is a light metal. It is three times lighter than steel. It is very versatile and easy to handle. This also makes it suspectible to dents and damages.

It is soft metal to form and a difficult metal to weld.

Aluminium can be anodized to improve its surface quality.

We can offer parts from Aluminium in grade 1100-0, 3003-0 etc.

Brass is an alloy of copper and zinc. It has a reasonably good corrosion resistance property.

Parts made from brass are very attractive as they shine like gold when properly maintained and cleaned.

P.P. Impex India invites you to discuss your specific requirement so a suitable composition of copper /zinc can be selected.

Copyright © 2024 All rights reserved by Byldr | Design and Developed By Arsh Infosystems