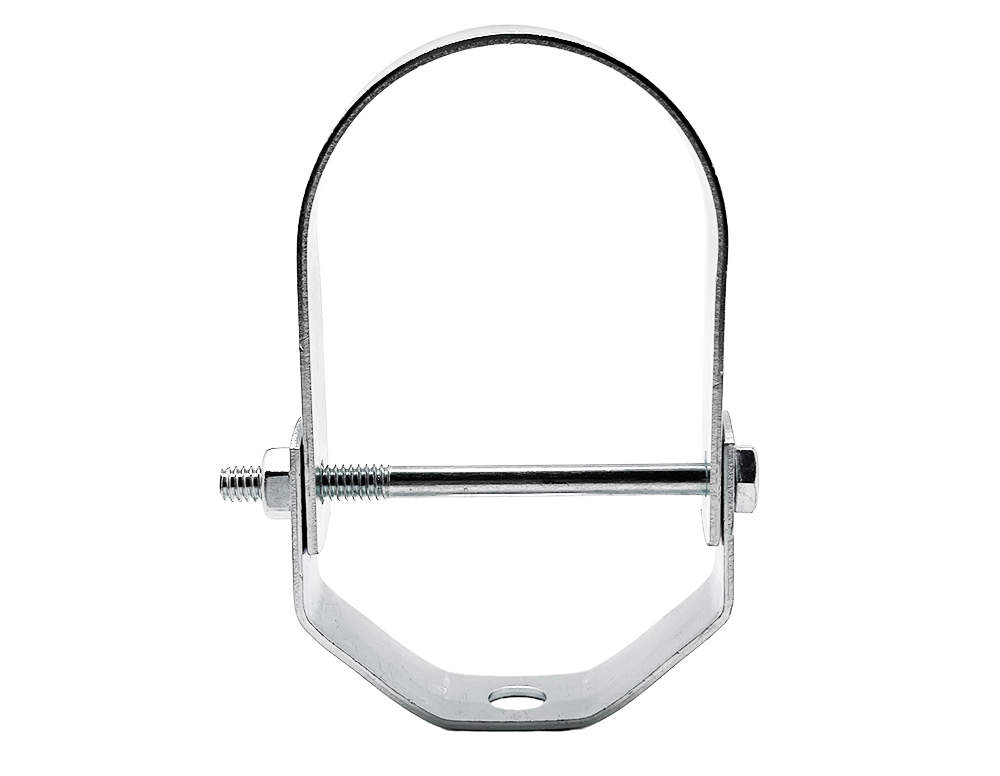

Clevis Hanger

Technical Specifications:

| Specification | Value |

| Material | Mild Steel. Other Materials Like Stainless Steel can be provided on request |

|---|---|

| Sizes | 1/2" to 30" |

| Finishes Available | Plain, Electro-Galvanised, Hot-dip Galvanised, Zinc Flake,Epoxy Coated. |

| Max Temp | 110° C |

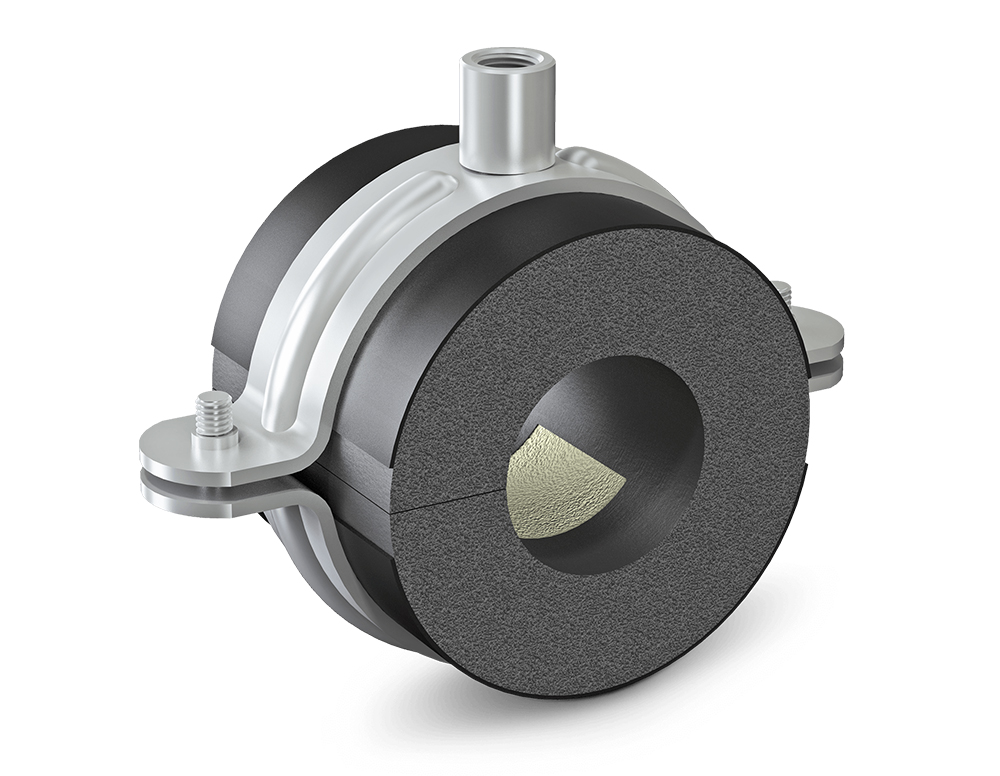

| Rubber Quality | Can be provided with EPDM Rubber on request |

| Max Load | As Per Size |

Application/Details:

Clevis Hangers are used for suspension of pipes. Clevis Hangers are especially used to install drainage pipes or sloped runs. Clevis Hangers provides for sizeable and for an elevation adjustment. Clevis Hangers allows pipes to move naturally. It also allows for vertical adjustments. The upper nut of the Clevis Hanger, when locked in position, helps in prevention of loosening due to vibrations in pipe and the Lower nut helps adjust the piping to proper elevation.

EDPM Rubber Lining with Clevis Hanger, can also be provided as per requirements of the customers. The EPDM lining on the Clevis Hanger offers superior support and resistance. Whether for industrial or commercial applications, our Clevis Hanger not only enhances the structural integrity of your piping system but also helps prevent vibrations and noise, contributing to a more efficient and quieter operation. Trust in our Clevis Hanger to deliver reliable performance and support.

Industries:

Clevis Hanger is widely used in Fire Fighting, MEP, building and infra, Oil and Gas Industries.

Construction:

Generally,Clevis Hangers include a yoke that connects to your support overhead. They also use a metallic loop to cradle your pipe. This cradle leaves room for vertical adjustment and harnesses your pipes securely in the air.

Technical Sheet:

| Product Code | Nominal Pipe Size | Pipe Od | Material Dimension (MM) | Hanger Rod | Cross Bolt | Max Load | ||

| (IN) | (MM) | (MM) D | HIEGHT | TOP HOLE DIA. | SIZE ( R ) | DIA. | (KG) | |

| DURAFIX-B-02001 | 1/ 2” | DN15 | 21.3 | 68 | 11 | M10 | M8 | 350 |

|---|---|---|---|---|---|---|---|---|

| DURAFIX-B-02002 | 3/ 4” | DN20 | 26.7 | 72 | 11 | M10 | M8 | 350 |

| DURAFIX-B-02003 | 1” | DN25 | 33.4 | 76 | 11 | M10 | M8 | 350 |

| DURAFIX-B-02004 | 1 1/ 4” | DN32 | 42.1 | 87 | 11 | M10 | M8 | 350 |

| DURAFIX-B-02005 | 1 1/ 2” | DN40 | 48.2 | 97 | 11 | M10 | M8 | 350 |

| DURAFIX-B-02006 | 2” | DN50 | 60.3 | 114 | 11 | M10 | M8 | 350 |

| DURAFIX-B-02007 | 2 1/ 2” | DN65 | 73 | 142 | 13 | M12 | M10 | 780 |

| DURAFIX-B-02008 | 3” | DN80 | 88.9 | 165 | 13 | M12 | M10 | 780 |

| DURAFIX-B-02009 | 4” | DN100 | 114.3 | 202 | 13 | M12 | M10 | 780 |

| DURAFIX-B-02010 | 5” | DN125 | 141.3 | 236 | 13 | M12 | M12 | 1250 |

| DURAFIX-B-02011 | 6” | DN150 | 168.3 | 278 | 13 | M12 | M12 | 1250 |

| DURAFIX-B-02012 | 8” | DN200 | 219.1 | 338 | 13 | M12 | M12 | 2100 |

| DURAFIX-B-02013 | 10” | DN250 | 273.1 | 419 | 17 | M16 | M16 | 2100 |

| DURAFIX-B-02014 | 12” | DN300 | 323.8 | 490 | 21 | M20 | M20 | 2100 |

| DURAFIX-B-02015 | 14” | DN350 | 355.6 | 556 | 21 | M20 | M20 | 3800 |

| DURAFIX-B-02016 | 16” | DN400 | 406.4 | 610 | 25 | M24 | M20 | 3800 |

| DURAFIX-B-02017 | 18” | DN450 | 457.2 | 675 | 25 | M24 | M24 | 4000 |

| DURAFIX-B-02018 | 20” | DN500 | 508 | 715 | 32 | M30 | M24 | 4000 |

| DURAFIX-B-02019 | 24” | DN600 | 609.6 | 850 | 32 | M30 | M24 | 9400 |

| DURAFIX-B-02020 | 30” | DN750 | 762 | 995 | 32 | M30 | M24 | 9400 |