Government Recognized Export House

Government Recognized Export House

At BYLDR, we understand that brands may require unique design and specific requirements as per their applications for their pipe clamps.

Moreover, if you don’t find the product you are looking for on our website then we can develop and manufacture it for you.

This is because, we offer OEM solutions, where we can make customised designs of the pipe clamps as per the requirements of the brand. It can be the design of the pipe clamps, the material used, the finishes, sizes or a different type of product that we do not make yet etc.

Pipe Leakages can be expensive as it leads to costly repairs by welding or replacing the patch of the pipe which has leaked. Furthermore, the line needs to be shut down resulting in interrupted supply of water etc. The Leakage clamps are a quick solution for this problem. It can be used a s permanent or a temporary solution to fix the leakage.

We were given some design to develop this product. This involved fine tuning of the design to suit the required pipe diameter. Moreover, the suitable test equipments were setup to perform the testing of the clamps on pressurised lines to check the optimal working pressure and the bursting pressure.

We have successfully supplied this product to our customer and many repeat orders are place for the same.

We understand that each brand and company may have a unique design of their pipe clamps which they require. This may be for special application or for using their product design as a tool for brand identification.

One of our customers in Europe, wanted a unique design to be made for their pipe clamps.

We understood the task and developed new tools to make this design of pipe clamps.

All the required sampling and testing was done and approved. We have successfully created the setup to mass produce the pipe clamp of that design.

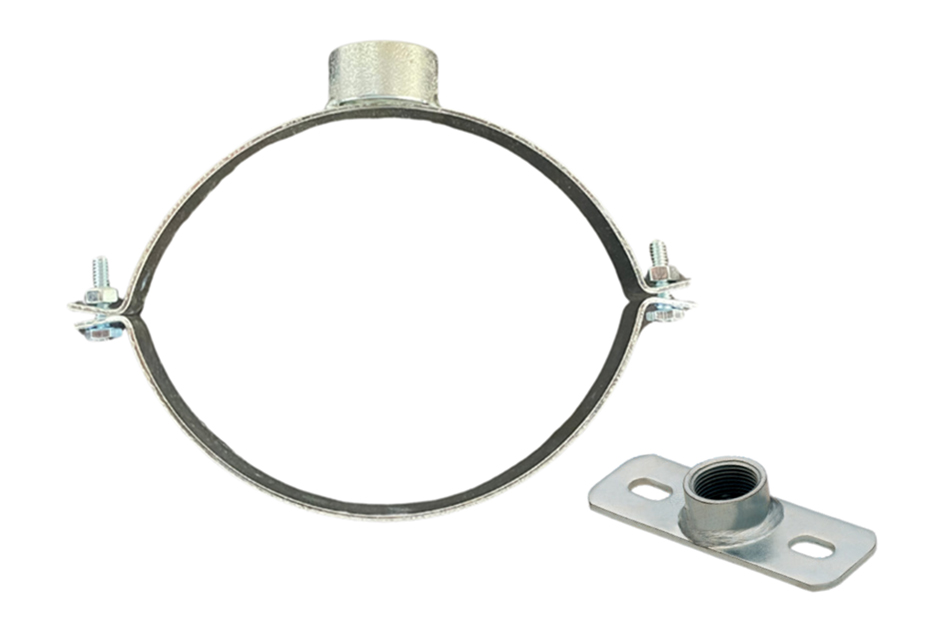

A project from an Australian customer required making pipe clamps with almost 360 degrees holding of the pipe’s circumference. The pipes were CI pipes which are heavier and required use of 3mm Carbon Steel Material to be used with at width of clamp at 30mm.

We made these clamps in various sizes (from 63mm pipe diameter to 280 mm pipe diameter) and submitted the pilot samples. On approval of the pilot samples we received the order from the customer for a larger quantity.

The Pipe support clamps for one of our middle eastern customers involved making a Boss with seamless pipe.

Normally the Boss on the pipe support clamp is made of Nut or a Nail. However, this customer wants to fix heavy pipe and hence they wanted boss to be made from Seamless pipe with BSP internal threads in it.

Also fixing of the collar to the pipe body cannot be done with spot welding operation like it is done normally. So, we setup a MIG welding booth for this product.

We successfully completed this order and are happy to have worked to suit our customer’s needs.

You can visit the Quality and Facilities page for more information of our capabilities.

Copyright © 2024 All rights reserved by Byldr | Design and Developed By Arsh Infosystems